When forces are applied on a body in such a manner that the body is still in static equilibrium, it is deformed to a small or large extent depending upon the nature of the material of the body and the magnitude of the deforming force. The deformation may not be noticeable visually in many materials but it is there. When a body is subjected to a deforming force, a restoring force is developed in the body. This restoring force is equal in magnitude but opposite in direction to the applied force. The restoring force per unit area is known as stress. If F is the force applied normal to the cross–section and A is the area of cross section of the body,

Magnitude of the stress = F/A (9.1)

The SI unit of stress is N m–2 or pascal (Pa) and its dimensional formula is [ ML–1T–2 ].

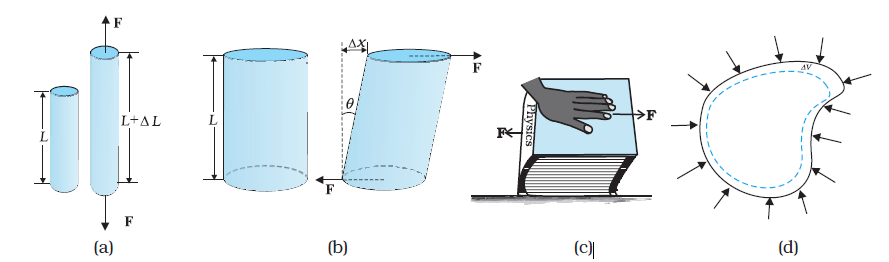

There are three ways in which a solid may change its dimensions when an external force acts on it. These are shown in Fig. 9.2. In Fig.9.2(a), a cylinder is stretched by two equal forces applied normal to its cross-sectional area. The restoring force per unit area in this case is called tensile stress. If the cylinder is compressed under the action of applied forces, the restoring force per unit area is known as compressive stress. Tensile or compressive stress can also be termed as longitudinal stress.

In both the cases, there is a change in the length of the cylinder. The change in the length ∆L to the original length L of the body (cylinder in this case) is known as longitudinal strain.

Longitudinal strain  (9.2)

(9.2)

However, if two equal and opposite deforming forces are applied parallel to the cross-sectional area of the cylinder, as shown in Fig. 9.2(b),

there is relative displacement between the opposite faces of the cylinder. The restoring force per unit area developed due to the applied tangential force is known as tangential or shearing stress.

Robert Hooke

(1635 – 1703 A.D.)

Robert Hooke was born on July 18, 1635 in Freshwater, Isle of Wight. He was one of the most brilliant and versatile seventeenth century English scientists. He attended Oxford University but never graduated. Yet he was an extremely talented inventor, instrument-maker and building designer. He assisted Robert Boyle in the construction of Boylean air pump. In 1662, he was appointed as Curator of Experiments to the newly founded Royal Society. In 1665, he became Professor of Geometry in Gresham College where he carried out his astronomical observations. He built a Gregorian reflecting telescope; discovered the fifth star in the trapezium and an asterism in the constellation Orion; suggested that Jupiter rotates on its axis; plotted detailed sketches of Mars which were later used in the 19th century to determine the planet’s rate of rotation; stated the inverse square law to describe planetary motion, which Newton modified later etc. He was elected Fellow of Royal Society and also served as the Society’s Secretary from 1667 to 1682. In his series of observations presented in Micrographia, he suggested wave theory of light and first used the word ‘cell’ in a biological context as a result of his studies of cork.

Robert Hooke is best known to physicists for his discovery of law of elasticity: Ut tensio, sic vis (This is a Latin expression and it means as the distortion, so the force). This law laid the basis for studies of stress and strain and for understanding the elastic materials.

As a result of applied tangential force, there is a relative displacement ∆x between opposite faces of the cylinder as shown in the Fig. 9.2(b). The strain so produced is known as shearing strain and it is defined as the ratio of relative displacement of the faces ∆x to the length of the cylinder L.

Shearing strain  = tan θ (9.3)

= tan θ (9.3)

where θ is the angular displacement of the cylinder from the vertical (original position of the cylinder). Usually θ is very small, tan θ is nearly equal to angle θ, (if θ = 10°, for example, there is only 1% difference between θ and tan θ).

It can also be visualised, when a book is pressed with the hand and pushed horizontally, as shown in Fig. 9.2 (c).

Thus, shearing strain = tan θ ≈ θ (9.4)

In Fig. 9.2 (d), a solid sphere placed in the fluid under high pressure is compressed uniformly on all sides. The force applied by the fluid acts in perpendicular direction at each point of the surface and the body is said to be under hydraulic compression. This leads to decrease in its volume without any change of its geometrical shape.

Fig. 9.2 (a) A cylindrical body under tensile stress elongates by ∆L (b) Shearing stress on a cylinder deforming it by an angle θ (c) A body subjected to shearing stress (d) A solid body under a stress normal to the surface at every point (hydraulic stress). The volumetric strain is ∆V/V, but there is no change in shape.

The body develops internal restoring forces that are equal and opposite to the forces applied by the fluid (the body restores its original shape and size when taken out from the fluid). The internal restoring force per unit area in this case is known as hydraulic stress and in magnitude is equal to the hydraulic pressure (applied force per unit area).

The strain produced by a hydraulic pressure is called volume strain and is defined as the ratio of change in volume (∆V) to the original volume (V).

Volume strain  (9.5)

(9.5)

Since the strain is a ratio of change in dimension to the original dimension, it has no units or dimensional formula.