So far we have studied the electric currents induced in well defined paths in conductors like circular loops. Even when bulk pieces of conductors are subjected to changing magnetic flux, induced currents are produced in them. However, their flow patterns resemble swirling eddies in water. This effect was discovered by physicist Foucault (1819-1868) and these currents are called eddy currents.

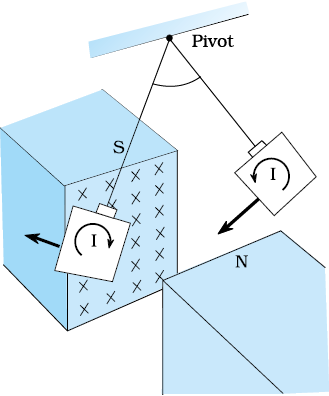

Consider the apparatus shown in Fig. 6.13. A copper plate is allowed to swing like a simple pendulum between the pole pieces of a strong magnet. It is found that the motion is damped and in a little while the plate comes to a halt in the magnetic field. We can explain this phenomenon on the basis of electromagnetic induction. Magnetic flux associated with the plate keeps on changing as the plate moves in and out of the region between magnetic poles. The flux change induces eddy currents in the plate. Directions of eddy currents are opposite when the plate swings into the region between the poles and when it swings out of the region.

Figure 6.13 Eddy currents are generated in the copper plate, while entering and leaving the region of magnetic field.

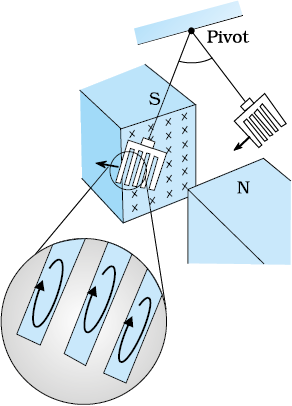

If rectangular slots are made in the copper plate as shown in Fig. 6.14, area available to the flow of eddy currents is less. Thus, the pendulum plate with holes or slots reduces electromagnetic damping and the plate swings more freely. Note that magnetic moments of the induced currents (which oppose the motion) depend upon the area enclosed by the currents (recall equation m = IA in Chapter 4).

This fact is helpful in reducing eddy currents in the metallic cores of transformers, electric motors and other such devices in which a coil is to be wound over metallic core. Eddy currents are undesirable since they heat up the core and dissipate electrical energy in the form of heat. Eddy currents are minimised by using laminations of metal to make a metal core. The laminations are separated by an insulating material like lacquer. The plane of the laminations must be arranged parallel to the magnetic field, so that they cut across the eddy current paths. This arrangement reduces the strength of the eddy currents. Since the dissipation of electrical energy into heat depends on the square of the strength of electric current, heat loss is substantially reduced.

Figure 6.14 Cutting slots in the copper plate reduces the effect of eddy currents.

Eddy currents are used to advantage in certain applications like:

(i) Magnetic braking in trains: Strong electromagnets are situated above the rails in some electrically powered trains. When the electromagnets are activated, the eddy currents induced in the rails oppose the motion of the train. As there are no mechanical linkages, the braking effect is smooth.

(ii) Electromagnetic damping: Certain galvanometers have a fixed core made of nonmagnetic metallic material. When the coil oscillates, the eddy currents generated in the core oppose the motion and bring the coil to rest quickly.

(iii) Induction furnace: Induction furnace can be used to produce high temperatures and can be utilised to prepare alloys, by melting the constituent metals. A high frequency alternating current is passed through a coil which surrounds the metals to be melted. The eddy currents generated in the metals produce high temperatures sufficient to melt it.

(iv) Electric power meters: The shiny metal disc in the electric power meter (analogue type) rotates due to the eddy currents. Electric currents are induced in the disc by magnetic fields produced by sinusoidally varying currents in a coil.

You can observe the rotating shiny disc in the power meter of your house.